Protect Your Crane Service Providers with Crane Sentry® Hoist Monitoring

- Laser-View

- Nov 11, 2024

- 1 min read

In industries that rely on overhead cranes, safety and efficiency are paramount. With heavy loads being lifted and moved across large facilities, minor errors in operation can have significant consequences.

For example, when using wire rope hoists, two of the most common challenges are:

Side pull (also known as side loading)

Slack rope conditions

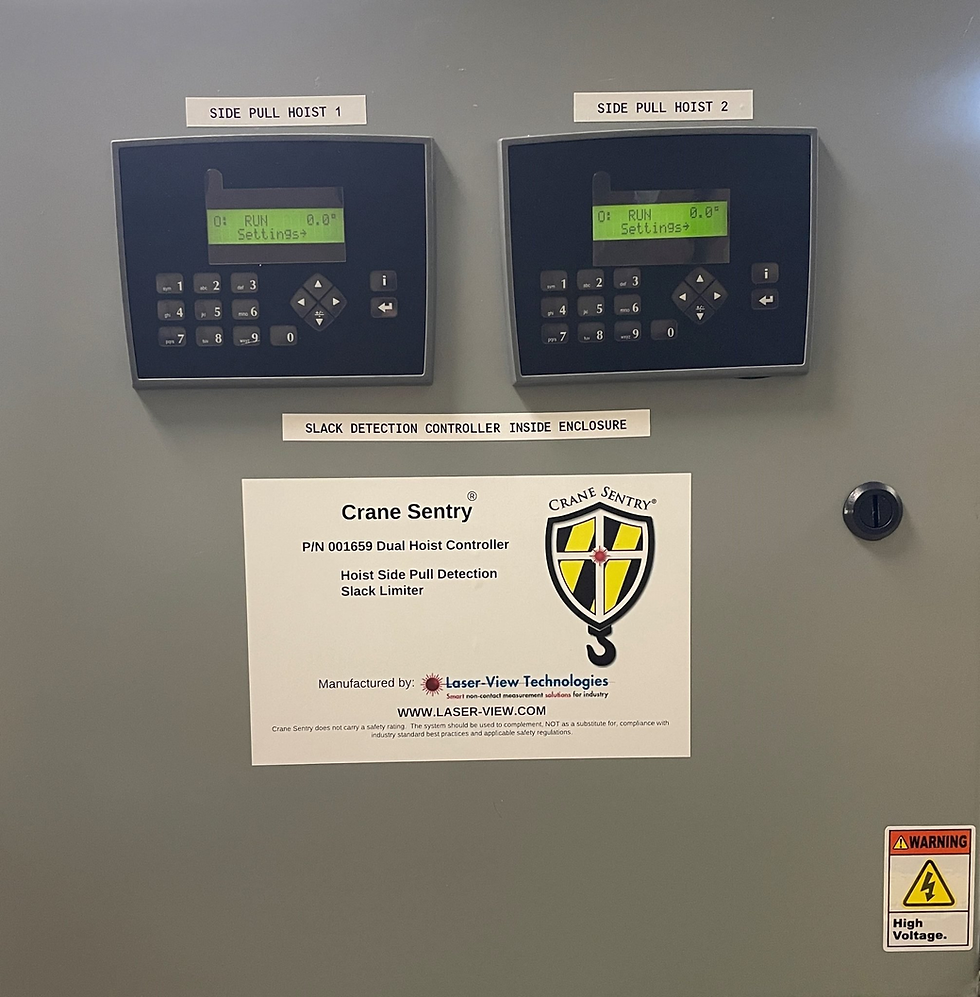

These problems can not only damage equipment but also endanger personnel. This is one of the reasons we designed Crane Sentry® Hoist Monitoring System, so crane operators have access to reliable dual hoist side pull detection and slack detection. Each system is designed to offer continuous hoist monitoring and real-time alerts if side pulling is detected.

A Recent Crane Sentry® Success Story

Recently, a crane service provider integrated both of these features into a pair of wire rope hoists. The system’s side pull sensor is mounted directly on the wire rope, while the load cells clamp onto the rope to detect slack. This setup makes it easy to monitor and maintain proper tension in the wire, preventing operational issues before they occur.

By installing this technology, this crane service provider can avoid costly accidents, improve safety standards, and reduce the wear and tear on their equipment.

If you’re interested in learning more about how Laser-View Technologies’ Crane Sentry® dual hoist side pull detection and slack detection system can enhance the safety and performance of your operations, we’re here to help. Reach out to us at info@laser-view.com for more information, and take the first step towards safeguarding your crane systems and operators.

Source: Jeanine Lubeck Protect Your Crane Service Providers with Crane Sentry® Hoist Monitoring - Laser-View Technologies

Comments